3 Things To Consider When Selecting Hydraulic Motors

Choosing the right hydraulic motor for your machinery or industrial application is critical. A poor choice can result in reduced performance, inefficiencies, or even equipment failure. Hydraulic motors are complex pieces of equipment designed to convert hydraulic energy into mechanical energy, and they come in various types and configurations. To ensure you’re making the right choice, there are several key factors to consider. In this post, you’ll learn about three essential aspects that should guide your decision-making.

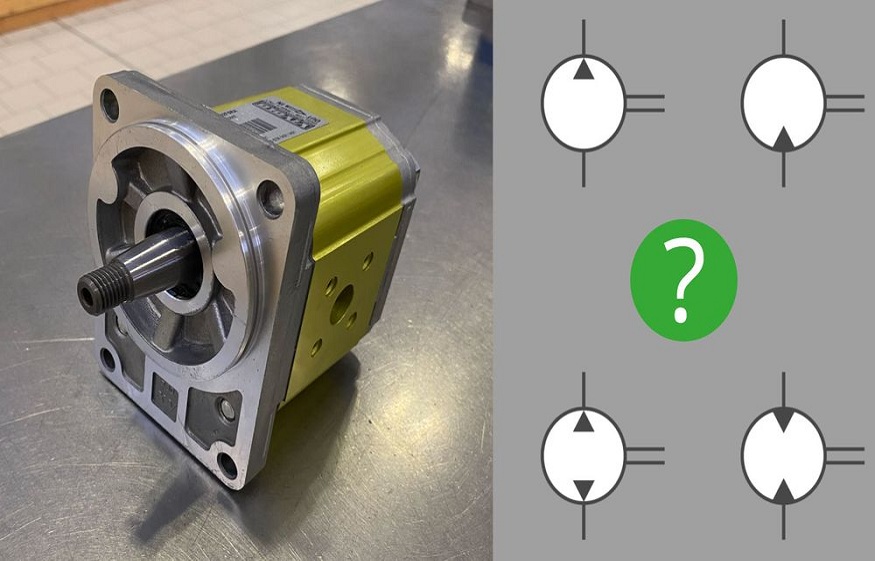

1. Type of Hydraulic Motor

Hydraulic motors come in three primary categories: gear motors, vane motors, and piston motors. Each has unique characteristics that make them suitable for specific applications. Gear motors, for example, are known for their durability and simplicity. They are ideal for low-speed, high-torque applications, such as in agricultural equipment or heavy construction machinery. Vane motors, on the other hand, are typically used in moderate-pressure applications where smooth operation is needed. Finally, piston motors are generally used for high-pressure applications, offering more efficiency but often at a higher cost.

Understanding the differences between these types is crucial because each motor has its pros and cons depending on the application. For example, if you’re dealing with high-pressure applications like heavy-duty construction equipment or hydraulic presses, piston motors may be the best option due to their efficiency. However, if you need a more budget-friendly solution for low to moderate pressure, gear motors or vane motors may be more appropriate.

2. Torque Requirements

Torque is another critical consideration when choosing a hydraulic motor. Hydraulic motors are often rated by their torque output, which is a measure of the force they can produce. The torque required for your application will depend on factors like the weight of the load being moved and the speed at which it needs to be moved. Motors that provide higher torque are essential for applications where heavy loads need to be moved at slow speeds. Conversely, lighter applications may require lower torque motors but with higher speeds.

Calculate your torque requirements before selecting a motor, as underestimating the needed torque could lead to equipment strain or even failure. Overestimating, on the other hand, can result in a motor that is larger and more expensive than necessary. Always keep in mind that hydraulic motors with higher torque usually operate at lower speeds, so there is often a trade-off between speed and power.

3. Operating Pressure and Flow Rate

Two other important factors are operating pressure and flow rate. Hydraulic motors are designed to work within specific pressure and flow rate ranges, and exceeding these limits can cause damage or reduce efficiency. Operating pressure refers to the amount of force exerted on the motor, while the flow rate refers to the volume of hydraulic fluid passing through the motor. Both of these factors will have a direct impact on the motor’s performance and its ability to perform certain tasks.

When selecting a hydraulic motor, you need to ensure that the motor’s pressure and flow rate capabilities match the demands of your application. For example, if you’re working in a high-pressure environment, you’ll need a motor that can withstand those conditions without failing. Additionally, a motor that operates efficiently at a lower flow rate can save energy and reduce wear on your system, extending the life of the motor. Always consult the manufacturer’s specifications and ensure the motor can handle the specific pressure and flow conditions of your operation.

Summing Up

Selecting the right hydraulic motor involves a careful evaluation of various factors, each of which plays a critical role in the motor’s performance and longevity. Investing the time and effort to choose the right motor from the start can save you significant costs and operational headaches in the long run.