Why UHMWPE Bed Liners Are the Best Choice for Heavy Load Trucks

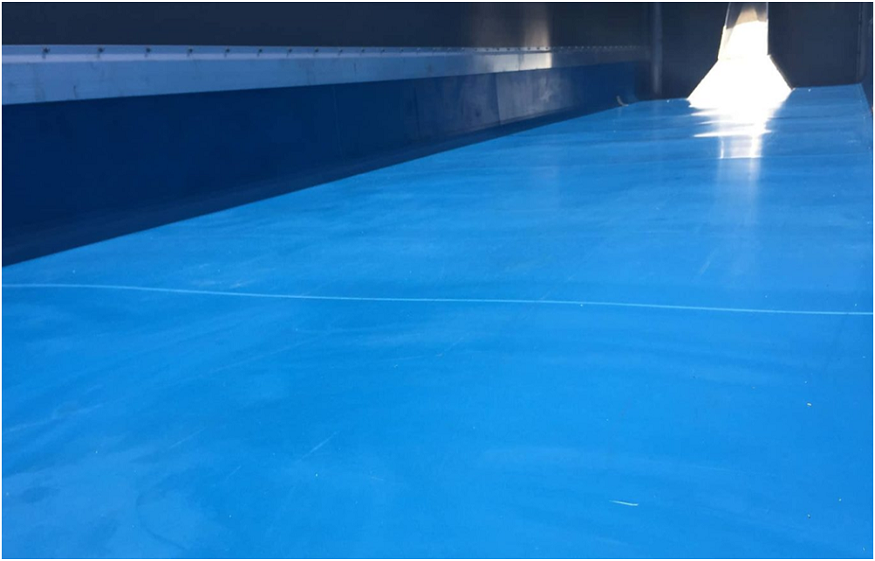

Bulk material handling comes with ongoing challenges such as sticky loads that refuse to release, abrasive materials causing accelerated wear, corrosive byproducts that damage trays, and environmental exposure that degrades structural integrity over time. For operators in heavy-duty haulage, the choice of liner material directly influences performance, safety, and maintenance.

Among available options, Ultra-High Molecular Weight Polyethylene (UHMWPE) bed liners are recognised for combining durability, a non-stick surface, and the strength to handle heavy loads.

This article explains why UHMWPE liners are a practical, high-performance choice for trucks transporting demanding loads.

Low Friction Surface Improves Load Release

UHMWPE liners are engineered with a non-stick surface that reduces friction between the truck body and the material transported. This means UHMWPE liners can handle cohesive materials, such as wet soil, clay, and mineral fines, without causing flow problems. The low-friction surface facilitates the smooth discharge of materials and allows unloading at lower tipping angles.

By minimising hang-ups, operators can tip with less interruption and avoid repeated lift cycles or tool-assisted clearing. This contributes to a more stable tipping process, supports quicker turnaround on site, and limits the risks associated with uneven discharge or retained loads.

Engineered to Absorb High-Impact Loads

Heavy-duty haulage often involves unpredictable loads such as sharp-edged rock, large metal ores, or excavation debris dropped from heights. Most truck body liners cannot handle such a load without showing signs of damage. However, UHMWPE liners are well-suited to these conditions, thanks to their high elastic limit, which allows them to absorb impact energy without cracking, denting, or deforming.

This impact resistance helps preserve the truck body by diffusing the force of repeated drops, particularly in environments such as mining or construction sites. By reducing wear and shielding the tray structure from direct shock, these liners support longer equipment life in some of the toughest conditions.

Resists Surface Wear from Abrasive Contact

Transporting harsh materials, such as gravel, crushed stone, or construction debris, causes constant friction against the liner surface. Over time, this abrasion can wear down conventional liners, thinning the material and exposing the tray, which can drive up maintenance requirements.

UHMWPE plastic bed liners are designed to withstand this grinding contact. Their wear-resistant properties help maintain a consistent surface profile, which extends the liner’s service life. This makes it especially valuable for operators handling abrasive loads across frequent haul cycles.

Corrosion Resistance

Unprotected steel trays are susceptible to rust and surface corrosion when exposed to materials such as wet waste, salt-infused soil, or organic byproducts. Moreover, metal liners are prone to corrosion, as they readily react to moisture. UHMWPE liners offer strong resistance to moisture and certain corrosive agents, helping to shield the truck body from pitting, staining, and long-term degradation.

This level of protection is especially valuable for operators handling loads that retain moisture or react with metal surfaces. These liners help extend vehicle lifespan and reduce costly surface repairs over time by preserving tray integrity across wet or chemically active load types. They provide a practical, lower-maintenance alternative to steel or aluminium liners.

Lightweight Yet Durable

UHMWPE liners offer a valuable weight advantage over steel or aluminium liners. Their lower density reduces the overall tare weight of the vehicle, allowing operators to maximise payload within legal limits.

Unlike most lightweight materials, UHMWPE combines low weight with high resistance to wear and deformation. This makes it a reliable option for operators who want to carry more material per trip without sacrificing durability or liner stability.

UV and Weather Resistance

UV radiation is a significant contributor to wear in outdoor transportation equipment, particularly in Australian conditions. Quality UHMWPE liners are available with UV stabilisation to resist sun damage over time. This helps prevent surface cracking, fading, or loss of integrity from prolonged exposure.

In addition to UV protection, these liners resist moisture, dust, and shifting weather without warping or becoming brittle. This makes them suitable for tipper bodies operating in uncovered yards, roadside conditions, or long-haul runs while maintaining consistent surface performance year-round.

Ultimately,bulk handling puts constant strain on transport equipment. UHMWPE liners meet these demands, offering a non-stick surface, strong wear and impact resistance, corrosion protection, and UV stability. They suit demanding sectors such as mining, construction, agriculture, and waste transport.

UHMWPE is a proven choice for fleets seeking longer service life and consistent tipping performance, and partnering with a trusted UHMWPE liner supplier ensures the liner is specified for your operational needs.