Exploring the Best Machine Tools and Top Equipment Machines in Saudi Arabia

Introduction:

Industrial development in Saudi Arabia has been quite dynamic, as it undergoes tremendous change in its manufacturing sector. The machine tools and equipment become important as the demand for precision and efficiency increases. This paper explores the world of the Saudi Arabian’s best machine tools and the top equipment machines which are a marvel of technology behind the country’s industrial might.

The Rise of Machine Tools in Saudi Arabia:

Machine tools are the spine of contemporary manufacturing and make it possible to make the most sophisticated parts with extreme accuracy. A wave of advanced machine tools drove the industrial revolution in Saudi Arabia. There are numerous types of equipment for various needs, such as lathes and milling machines to CNC routers, in the market.

Precision Redefined: CNC Machines Take Center Stage:

In the context of the Saudi Arabian industrial environment, one of the best players in this market is the CNC (Computer Numerical Control) machine. The marvels of engineering have changed the way people manufacture products by providing unprecedented accuracy and automation. Countries such as Saudi Arabia have adopted CNC machines in several industries ranging from aerospace to automotive since these machines can manufacture complicated components with close tolerances thereby achieving the required quality matching international standards.

Cutting-Edge Innovations in Metalworking:

Advanced metal-cutting solutions represent a critical element in the industrial landscape of Saudi Arabia, where the demand for metalwork is unprecedented. The advent of new efficiency has led to the use of the combination of laser cutting machines, water jet cutters, and plasma cutters. Such machines are accurate in metal shaping and support sustainable industrial practices as the country strives towards a greener economy.

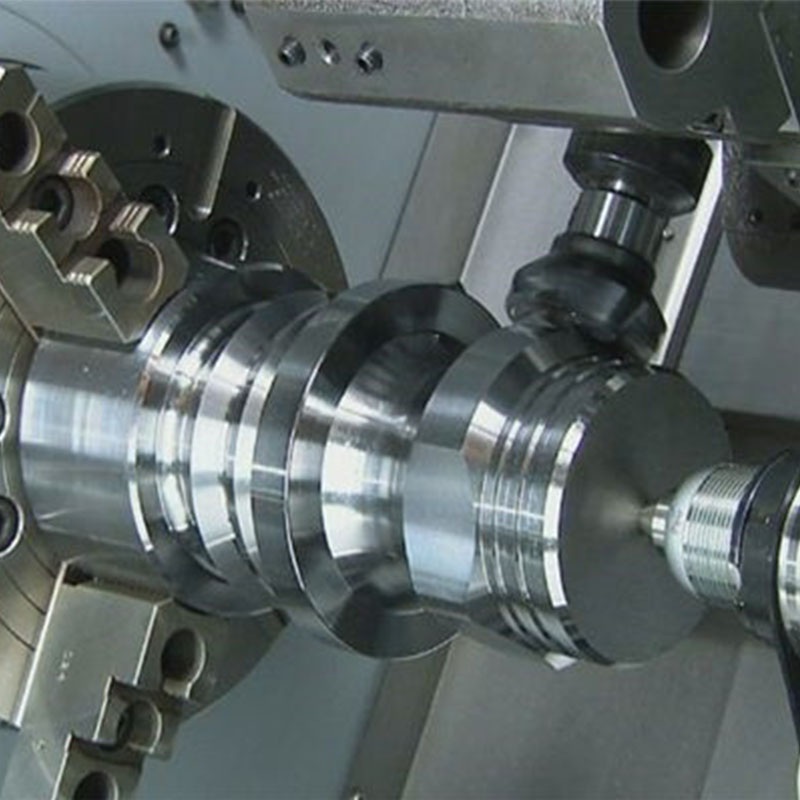

Turning Dreams into Reality: Lathe Machines in Saudi Arabia:

These age-old lathe machines are still important today and help to turn the raw materials into the finished products. The Saudi Arabian market is saturated with the most sophisticated lathe machines for use by both small-scale workshops as well as large-scale industries. These machines add to the versatility and precision that aid the country’s manufacturing abilities.

Robotics and Automation: A Glimpse into the Future:

Saudi Arabia is moving forward with technology and this involves implementing robotics and automation of manufacturing processes. Production is being made more efficient through the utilization of robotic arms as well as automated assembly lines, thus decreasing their dependence upon manual labor. This paradigm shift, however, raises productivity and creates safer and more predictable manufacturing conditions.

The Role of Top Equipment Machines in Saudi Arabia’s Infrastructure:

The sophisticated machine tool industry notwithstanding, Saudi Arabia is largely dependent on high-tech equipment machines in construction and infrastructure. The nation’s skyline is being shaped by excavators, bulldozers, and cranes which are unsung heroes. The need for strong and dependale construction equipment is also very high considering the mega projects of NEOM and the Riyadh Metro.

Innovations in 3D Printing: Shaping the Future:

The world is now engaging with additive manufacturing and SA is also embracing its 3D printing technologies. This revolutionary process enables the manufacture of extremely intricate shapes and specialized parts in record time. The use of 3D printing in industrial manufacturing in Saudi Arabia is paving the way for a new trend in industry.

Ensuring Quality through Inspection and Measurement Tools:

However, without inspection and measurement tools, it would not be possible for the companies to achieve excellence. These latest metrological technologies are an indication of Saudi Arabia’s commitment not to compromise on its quality products. The use of Coordinate Measuring Machines (CMMs), optical inspection systems, and laser scanners are employed to certify that their components meet the global market’s stringent standards of accuracy and precision.

Additive Manufacturing in the Aerospace Sector:

The use of additive manufacturing in making Saudi Arabia’s aircraft parts is shaping the new way of producing airplane parts in this burgeoning aerospace industry. 3D printing technology helps to produce light structures with complicated shapes that boost fuel economy and environmental friendliness. Saudi Arabia utilizes an innovative approach in this sector which shows that they are ready to adopt sophisticated manufacturing processes and become one of the world’s superpowers that lead the global aerospace industry.

Integration of Augmented Reality (AR) in Machinery:

One of the most noticeable features of the best equipment machines in Saudi Arabia is the inclusion of advanced reality (AR ) techniques. This innovative approach improves operational performances by enabling real-time superimposed data, interactive guides, and instructions for machine operators. AR is not only for training people but also helps in reducing downtime due to quick troubleshooting and therefore becomes an indispensable tool used by leading equipment manufacturing companies in the Saudi Arabian market.

Human-Machine Collaboration: Embracing Industry 4.0:

Saudi Arabia’s manufacturing landscape is being shaped through the adoption of the fourth industrial revolution principles. Smart factories incorporate sensors, IoT, and live analytics for smooth communication between machines, which promotes predictive maintenance that reduces downtime. However, this evolution towards human-machine collaboration increases productivity and places Saudi industries at the cutting edge of the fourth industrial revolution.

Market Dynamics and Global Collaboration:

The machine tool supply industry in Saudi Arabia is not independent; it is open and connected to the world economy. The industrial capabilities in this country are continuously developed by collaborating with foreign manufacturers. At the same time, there is an exchange of technological information with other countries. Saudi Arabia builds partnerships to enable it to access the latest knowledge across the globe to remain ahead of the competition.

Digital Twin Technology for Predictive Maintenance:

The first in Saudi Arabia for the implementation of the digital twin technology is in the top equipment machines. Manufacturers use simulation of their machines to observe performance in real and anticipate maintenance. This approach reduces the unexpected stoppage period, extends machine life, and saves money, making digital twin technology a major player in the reliability and longevity of top equipment machine in Saudi Arabia industrial landscape.

Conclusion:

To conclude, there is an evolutionary trend in the landscape of machine tools and equipment machines in Saudi Arabia driven by innovation and superior quality. The country is charting a course toward a future that combines precision, efficiency, and sustainability, from CNC machines and robotics to 3D printing and greener practices respectively. The global community observes that Saudi Arabia makes investments in the nation’s industrial sector and the world awaits this future maker.